Trust is Good, Control is Better

We put components, assemblies and processes through their paces to nip potential problems in the bud.

Quality Management

We see our organization, our products and services, and all the people belonging to our organization interacting as a total product. With this we offer functional as well as emotional and social benefits.

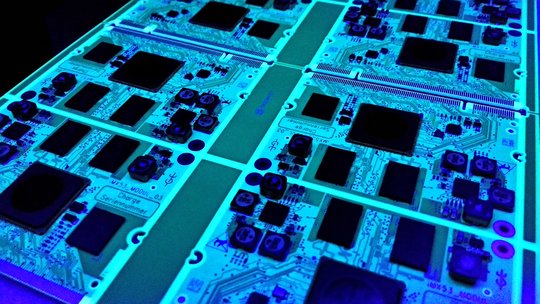

Each product is subjected to appropriate tests based on the requirements and risks. As a standard, the material data of all components, the process parameters of the production and the measured values of the end-of-line tests for each individual serial number are automatically documented in a database.

In order to meet the requirements and wishes of our important stakeholders - first and foremost our customers - we work according to the principles of the EFQM model.

Quality Assurance

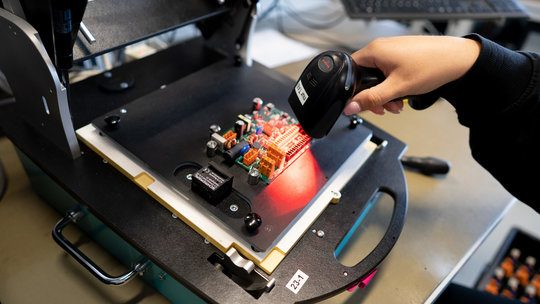

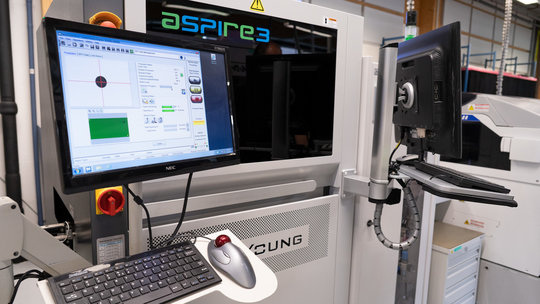

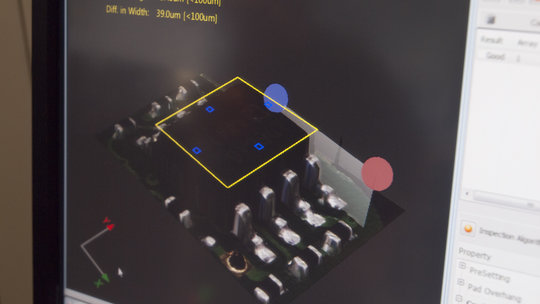

The quality assurance department has numerous options for the random testing of prototypes and series products. In the metallography laboratory and with our own X-ray equipment, components and assemblies can be put through their paces and literally x-rayed.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/2/csm_Ginzinger_Quality_Lan_XRay_QS_29a594fda0.jpg)