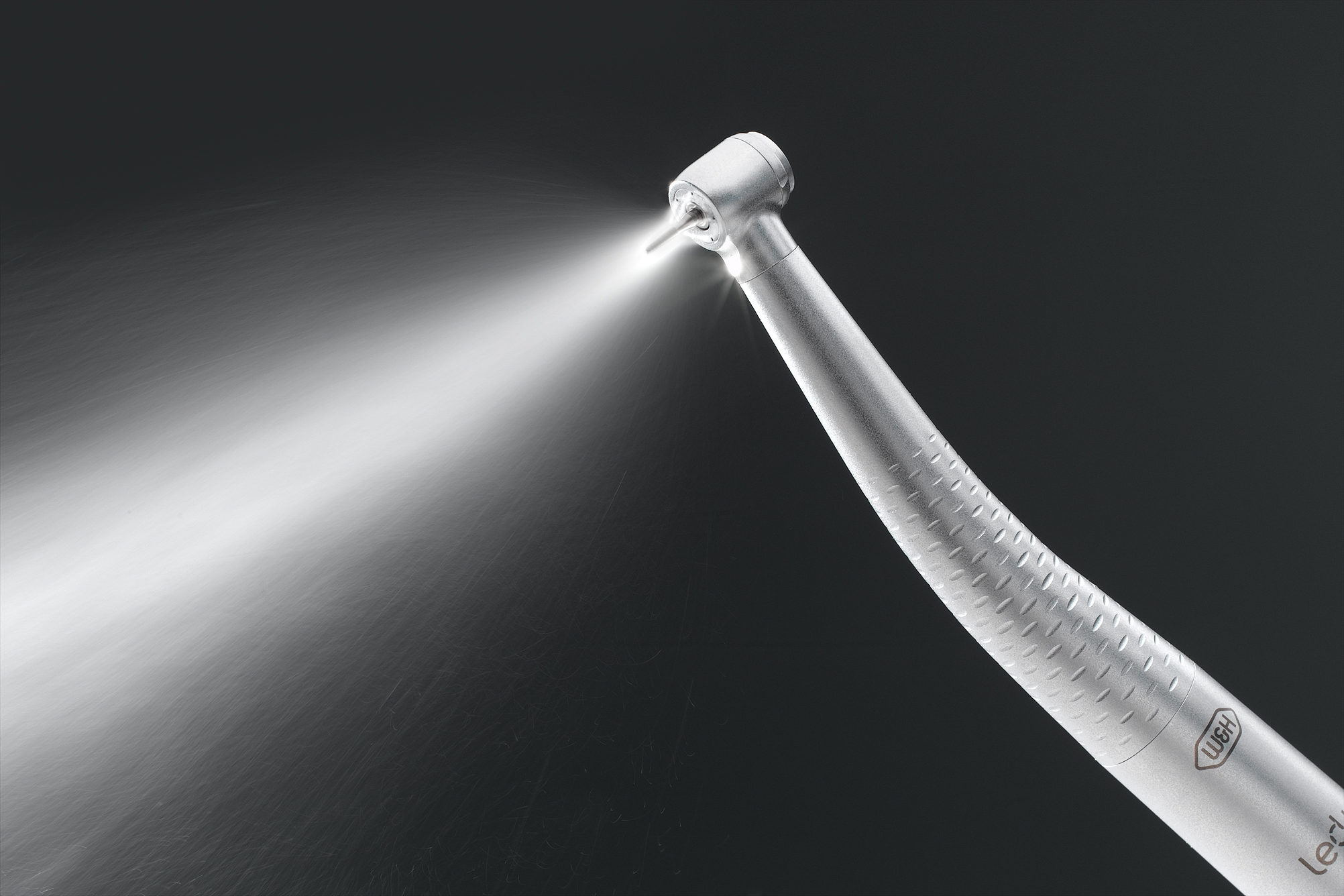

Probably few people look forward to it: going to the dentist in anticipation of an unpleasant and painful procedure. A visit in connection with a surgical procedure usually gets on your nerves or under your skin in the truest sense of the word. In order to make surgical procedures in the dental area as gentle and painless as possible, dental surgeons like to resort to the surgical method using piezo technology. The ultrasonic waves transmitted by the dental device act exclusively on calciferous tissue, i.e. on bones or teeth.

PIEZOMED PLUS

about the customer

W&H Dentalwerk Bürmoos GmbH

The international W&H Group with headquarters in Bürmoos (Austria) is a global leader in the development and manufacture of medical technology products. With around 1200 employees worldwide, W&H exports its products to over 130 countries. High-quality product and service solutions, a modern corporate structure, a strong focus on research and development, and social responsibility make W&H a locally and globally successful family business.

"Ginzinger has been a development partner for W&H for many years. Together, we have already successfully implemented numerous projects."

Flexible to use

The new Piezomed module

The Piezomed module is the successor to the Piezomed table-top unit and can be used in combination with Implantmed, the W&H product for placing dental implants. The Implantmed Plus thus represents the basis of the system. By simply coupling the Piezomed module, the physician is prepared for a wide range of surgical applications. The combined unit is operated by means of the Implantmed MMI developed and produced by Ginzinger.

![[Translate to Englisch:] W&H Implantmed Modernste Zahnarzttechnologie](/fileadmin/_processed_/6/9/csm_Ginzinger-referenz-wh-piezomed-Controlunit_f33213d4eb.jpg)

"The new Piezomed modules are a world first in our product segment. Thanks to the modular concept, it is now possible for the user to share the advantages of rotating electric motors and vibrating piezo instruments in a very small space."

many features

Hardware & Software

The new generation of the dental device offers many features. For example, the Piezomed software automatically recognizes which tip from the three available tip groups is attached to the handpiece. The handpiece has an LED base including cable and can be thermodesinfected and sterilized. The LED ring illumination on the handpiece guarantees ideal illumination of the surgical field. This is also produced at Ginzinger. In addition, the user now also has more power at his disposal: instead of the previous 20 watts, it is now 24 watts. The new W&H system concept will enable individual electronic components to be used more flexibly in the future, even by manufacturers of complete treatment chairs.

Project start

New board concept & improved software

Two boards are installed in the Piezomed: The drive board and the tip detection board. The drive board controls the installed piezo motor and causes it to oscillate at a certain frequency, the so-called resonance frequency. It must then be operated constantly at this frequency. The tip detection circuit board reliably detects which tool is currently attached to the handpiece in currently three power classes or groups. In the course of a redesign at Ginzinger, the drive board was reduced in size, equipped with improved power (from the previous 20 watts to a maximum of 24 watts) and optimized in terms of cost. Thanks to the modular design, W&H can also use the drive board in other products.

Technical challenges

In hardware development, the biggest challenges during the redesign and modularization were probably the thermal management for the drive board, the control of the drive, and keeping the installed piezo motor at resonant frequency. It was not easy to design the drive board in such a way that it would not heat up too much in the predefined, very tight space despite the high output power.

The control of the drive primarily challenged the software team at Ginzinger electronic systems. The drive board consists of two controllers. One of them is a high-performance controller with a high-resolution timer. It takes over the complete power and frequency control, filters the power input of the other controller and sets the power at the drive of the handpiece. The second controller communicates with the display unit via CAN. A lot of know-how was required for the drive software. The focus was on optimizing the performance of the control technology.

"The control of the piezo drive is very demanding. The material to be cut can have very different degrees of hardness. As soon as the cutting edge has penetrated bone or tooth substance, the resonance point of the control shifts. The power loss generated during cutting must be minimized by means of software."

Longstanding partnership

Successful market launch

The various attachments for the handpiece were also a challenge for the software developers, because the control must always be optimally parameterized - regardless of the tip. It is up to the software to recognize and control the optimal performance of the respective tip. The application on the display and the firmware of the communication controller on the drive were programmed by W&H. The firmware for piezo control, tip detection, control algorithms and optimization of power consumption came from Ginzinger.

The Piezomed module has already been successfully introduced to the market by W&H and is being produced in series by Ginzinger.

Embedded Systems in Medical Technology

Standards and certifications

The use of technology in medicine requires strict measures to exclude malfunctions and to permanently ensure quality. These measures must be adhered to and documented throughout the entire product life cycle.

Some important medical technology guidelines and standards that developers must be aware of are:

- Medical Device Regulation MDR of the EU

- IVDR - In-vitro Diagnostic Device Regulation of the EU

- EN ISO 13485 - Management system for design and manufacture of medical devices

- EN 60601 - set of standards on medical electrical equipment and systems

Easy operation and use

In critical environments, such as treatment rooms or laboratories, care must be taken to keep HMI operating surfaces and switching elements germ-free. Today, the operation of medical devices is simplified by means of voice input and output. Artificial intelligence supports their use, for example by making suggestions for the interpretation of images or measurement results in diagnostics and relieving the user of the burden of making important decisions.

Energy Management & Computing Power

Increasing miniaturization and computing power of electronics and embedded systems today enable medical devices that are small and compact to collect data and make control decisions directly on the patient. Microcontrollers with minimal power requirements are combined with sophisticated energy management for long-lasting and battery-saving operation.

Safety & Reliability

Medical devices must function permanently and reliably. The risk of malfunctions during operation must be minimized as early as the development stage. To this end, comprehensive risk analyses must be carried out on an ongoing basis. Based on these analyses, measures are derived to further minimize potential threats. Redundant systems, sophisticated monitoring functions in hardware and software, and components that meet the prescribed standards are used.