Challenge

With a lot of intelligence to the world market leader

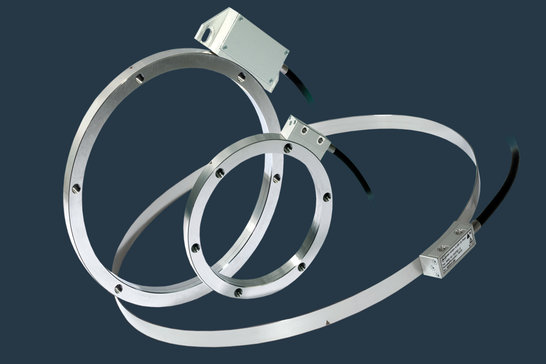

Measuring systems for the acquisition of geometric quantities for precise, dynamic positioning tasks must function reliably in precision machines under harsh environmental conditions. The AMOSIN inductive scanning system from AMO GmbH combines the accuracy of optoelectronic and the robustness of magnetic methods.

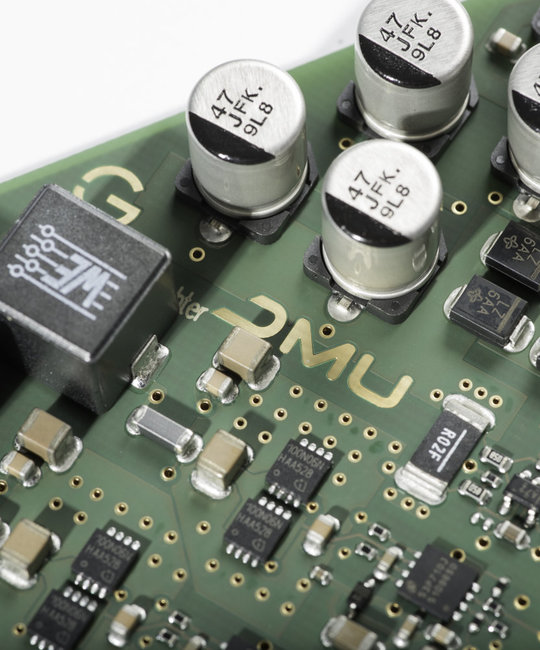

Ginzinger electronic systems has been handling the production of highly complex electronics for AMO GmbH for more than twenty years.

Highly precise

AMO GmbH

AMO GmbH, based in St. Peter am Hart, realizes measuring systems for geometric quantities based on the AMOSIN® inductive scanning principle, which combines the accuracy of optoelectronic and the robustness of magnetic methods.

highly complex electronics

With a lot of intelligence to the world market leader

AMO's products are mainly used in machine tools and other related sheet metal and metalworking equipment. However, they are also used in medical technology, for printing machines and special equipment for electronics and semiconductor production, automotive and aerospace industries.

"We prefer suppliers who are located within a radius of about 100 kilometers. Of course, problems or questions arise again and again in the cooperation with our suppliers. And the shorter the travel distances, the faster and more cost-effectively such problems can be solved.