Latest

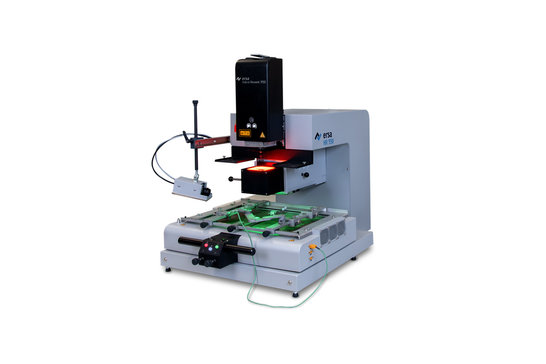

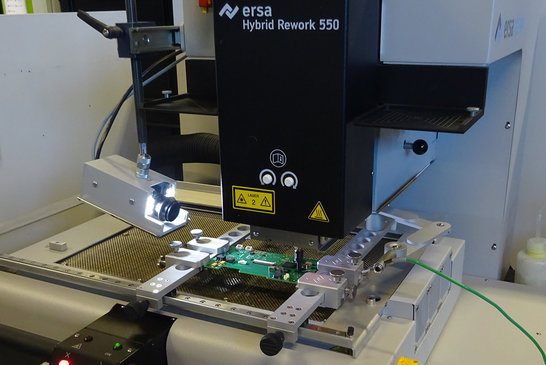

New rework station with infrared technology

This ensures efficient and precise processing of surface-mounted components in production.

The ERSA HR 550 rework station has been an integral part of our commissioning and repair department for about a year.

It enables the efficient and precise processing of surface-mounted components (SMD), in particular BTC (Bottom Termination Components), BGA, LGA, and QFN components.

With this technology, we always keep our finger on the pulse of the latest developments and ensure the highest quality in production and repair.

Areas of application

- Re-soldering of defective components that cannot establish a connection to the pads, e.g., due to a head-in-pillow (HiP) effect. This allows series defects to be rectified quickly and reliably.

- Repair of various assemblies

- Replacement of defective surface-mounted components with complex connections (BGA)

- Highest precision and reliability, even with complex components with underside connections that are traditionally difficult to process.

Technical features

- Heating technology

- Infrared radiation from above and below for even heat distribution

- Includes precisely adjustable temperature control

- Flexible heating surfaces thanks to independently controllable zones that adapt to different components - Nozzle system

- Variable nozzles (1–10 mm) for different component sizes, quickly interchangeable. - Programmable soldering profiles

- Adaptable to component size, mass area, and PCB design. - Sensors & ease of use

- Ensures reliable processes through easy operation and step-by-step instructions. - Camera system

- Visual control of the soldering process in real time to ensure maximum quality.

The rework station enables complex components to be repaired reliably and series faults to be rectified efficiently. It ensures that our products achieve the highest quality and underlines our claim to be a technological leader in production.