Technology

Short circuit localization without guesswork

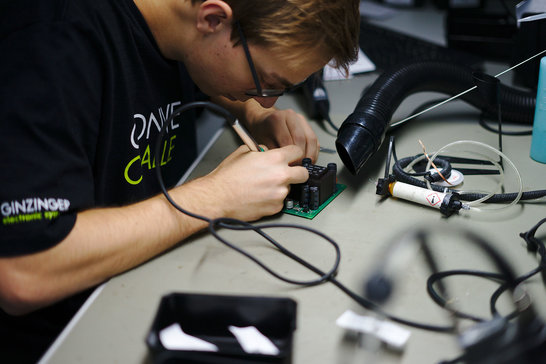

Short circuits on complex circuit boards cost time, nerves, and often entire assemblies. A new device in our repair technology makes troubleshooting significantly faster and more reliable, increasing repair rates and cost-effectiveness.

Effective short-circuit localization in repair service

Short circuits between supply levels such as 3.3 V, 5 V, and ground (GND) are among the most complex fault patterns in electronic repair. Especially with multilayer PCBs with multiple power or ground planes, classic troubleshooting is often a tedious guessing game that frequently leads to time and cost losses.

With the new Polar Toneohm 950A short-circuit locator, Ginzinger electronic systems now offers a powerful measuring device that addresses this very problem and significantly increases the repair rate.

The Toneohm 950A uses innovative Vector Plane Stimulus (VPS™) technology, which allows short circuits between supply planes on multilayer printed circuit boards to be quickly and accurately localized, even when conventional methods fail.

In practice

Four stimulus conductors are connected to the corners of the circuit board, typically to ground pads in the frame. A reference conductor is connected to the voltage level to be tested (e.g., 3.3V) and the affected network is scanned using a measuring or field probe. Directional arrows appear on the display, pointing directly toward the source of the short circuit.

In addition, the device emits an acoustic tone that becomes higher in pitch as it approaches the short circuit. Thanks to this combination of display and sound, the short circuit can usually be identified within a few millimeters after just three to four measurement movements.

Reinhard Schmeitzl, repair technician at Ginzinger, says of the new device:

“The Toneohm 950A has been in regular use at Ginzinger's repair service and in rework/commissioning for almost six months. The investment has already paid for itself, as almost 100% of short-circuit faults have been successfully identified and rectified.”

Multiple measurement modes

The Toneohm 950A covers various short-circuit situations:

- Track resistance measurement to directly measure low-resistance short circuits

- Track current measurement to detect current flows without conductor track interruption

- Plane shorts localization, ideal for short circuits between supply levels

- Field trace measurement to locate faults caused by magnetic fields

- Voltage tracking to detect low-resistance load faults

In most cases, a defective ceramic capacitor (Kerko) was the cause. After targeted replacement, the assembly is functional again. In some cases, layer short circuits that occur mechanically in the printed circuit board itself are also identified.

The advantages:

Economical and resource-efficient

- Significantly more repairs can be carried out

- Reduced spare parts costs

- More sustainable reuse of electronics

Faster solutions

- Less time spent locating short circuits

- Clear graphical and acoustic guidance, even for less experienced employees

Improved evidence and documentation

- In the case of faulty components or circuit boards, the origin can be precisely located and documented, e.g., with micrographs, which is an important aspect for handling complaints with suppliers.

Easy to use

- No lengthy training required – intuitive operation

With the Polar Toneohm 950A, Ginzinger relies on an efficient, precise, and sustainable solution for locating short circuits on complex printed circuit boards.

The device adds significant value to the repair service, benefiting both customers and the environment.