Latest

New addition to the machine park - selective soldering machine

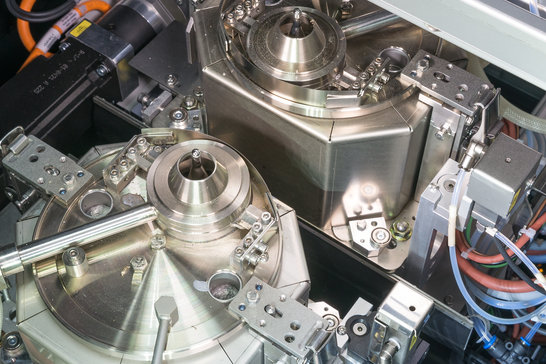

In order to also solder THT components quickly, fully automatically and with the highest precision, Ginzinger is investing in a new selective soldering system.

The miniaturization of assemblies is advancing relentlessly. Nevertheless, not all electronic assemblies can be realized exclusively with SMD components. In order to also solder THT components quickly, fully automatically and with the highest precision, Ginzinger is investing in a new selective soldering system. The ECOSELECT 4 is the latest selective soldering system from Kurtz Ersa. The compact system is ideally suited for small to medium-sized series where flexibility is paramount. It incorporates the latest machine technology.

The machine has a high-quality and continuous roller transport and is equipped with power convection. This ensures optimum homogeneous heating even for the most difficult components. A programmable precision spray fluxer with integrated spray jet control ensures the precise and economical application of flux, both in individual points and in entire paths.A configurable double-seal system makes it possible to work simultaneously with two different supplies and with solder nozzles of different diameters. Connector strips, for example, can be soldered quickly with a large-diameter nozzle, and hard-to-reach solder joints with a very narrow solder nozzle.

The highlights at a glance:

- Flexibly integrable soldering system: inline and batch operation

- VERSAFLOW4 technology

- PCB holder 508x508 mm

- up to two spray heads

- up to two supplies

- power convection

- double crucible y/z-variable

- automatic nozzle activation

- extension to full inline machine by stand-alone flux module

- VERSACAM solder wave measurement "on the fly

"The new selective soldering system offers several important advantages: One is the upgradeability to an inline machine. Throughput can thus be increased even further if required."

In addition to the aforementioned highlights of the new soldering system from Kurtz Ersa, two other important points were decisive for the acquisition of the system: process reliability and traceability. Because now there is a fully automated and above all controlled process behind the THT soldering.

"Solder temperature, solder duration and flux application now remain constantly the same," explains Berger. "And especially the temperature and the duration have a massive influence on the quality of solder joints. In addition, with the Ecoselect there is now also less residue on the circuit board. This makes it possible to immediately process assemblies further, for example, to paint them."

The acquisition of the ERSA selective soldering system was the next, logical step for Ginzinger electronic systems to remain flexible in the long term and to respond to customer requirements with the highest quality. "Our competitiveness in electronics production depends on the highest possible degree of automation," says Michael Berger.