Special

Electronics love care—and a good plan

Lifecycle management in electronics: Essential for long-lasting products, secure updates, protection against obsolescence, and continuous optimization right from the start.

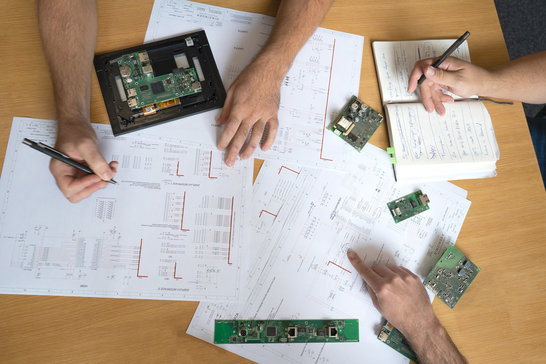

An electronic product has a life cycle. It is planned, developed, and produced. And then what? In reality, this is when the real challenge begins: product lifecycle management (PLM). Lifecycle management ensures that devices not only shine at launch, but also function reliably years later. Those who have full control over the entire product lifecycle save time, money, and stress while securing the trust of their customers.

Why lifecycle management?

- Comprehensive product maintenance

Products need maintenance—just like machines, cars, or software. Without regular maintenance, small problems creep in and can quickly become big ones. From spare parts supply and software updates to complete documentation: maintaining your products extends their service life and avoids expensive surprises.

- Alternatives for discontinued components

Obsolescence is the natural enemy of any long-term strategy. When key components suddenly become unavailable, there is a great need for action. Lifecycle management ensures that alternatives are examined and redesigns planned at an early stage. Ideally, this is done so well that end customers don't even notice.

- Rapid solutions to software problems

A small bug can have a big impact—for example, if it opens a security vulnerability or cripples functions. In good lifecycle management, bug fixing is just as much a part of the process as security monitoring. This allows vulnerabilities to be identified and eliminated quickly—before they become a problem.

- Continuous optimization of product and production

A lifecycle does not end with the first delivery. Production processes and technical solutions can be continuously improved. Lifecycle management is like a regular health check for your product: it identifies potential areas for optimization, simplification, or more cost-effective production.

- Consideration of the next product generation

Technology is developing rapidly – and so are your customers' expectations. Anyone developing a product today must also think about version 2.0. Lifecycle management creates the basis for seamlessly integrating new features, modern operating concepts, or smart networking – without having to start from scratch.

Well maintained lasts longer – even in electronics

Lifecycle management is not an add-on, but an essential part of modern product responsibility. Those who keep an eye on the entire lifecycle of their electronic products—from development to operation to replacement—not only ensure technical reliability, but also economic efficiency and customer satisfaction.

The next step? Analyze where your current product stands. Are there any known weaknesses? How well is the supply of components and updates secured? And what is the plan for the next generation? A structured view of the product lifecycle is always worthwhile—because it turns short-term success into a long-term success story.